NeoDen4 Pick and Place Automation Machine

■ Placement Rate up to 4,000CPH

■ Smallest size of 0201 to a largest size of TQFP240

■ Feeder Capacity of 48 pcs Feeders

NeoDen4 is designed to satisfy demands for high precision, high capacity, stable performance, and low cost. Its low cost makes it a great breakthrough for small and medium-sized enterprises with a limited budget.

The device has a lightweight body and occupies a small area. It features a user-friendly interface that does not require a professional SMT engineer, making it an entry-level device. This makes it especially suitable for laboratory research and development, samples, and prototyping.

Introduction

NeoDen4 is a desktop Pick and Place machine with a vision system. As a professional PnP machine designer and developer, NeoDen has been doing research in the SMT industry since 2010. The NeoDen4 is equipped with dual cameras, auto rails, auto electronic feeders, and 4 placement heads. It is capable of handling components such as 0201, BGA, and QFN. NeoDen4 is the best choice to satisfy all demands of high precision, high capacity, stable performance, and low cost.

NeoDen4, the 4th generation pick and place machine of NeoDen Tech, was independently designed and developed with patents and CE certificate.

Why Choose NeoDen4 Pick and place machine?

【High Precision and Capacity】 NeoDen4 is designed to satisfy demands for high precision, high capacity, stable performance, and low cost. Under factory test conditions, the placement rate is 4,000CPH with vision on and 7,500CPH with vision off. Its low cost makes it a great breakthrough for small and medium-sized enterprises with a limited budget.

【Advanced Vision System】 The machine is equipped with an up-looking and a down-looking camera, which use a patented image distortion processing algorithm to identify and calibrate different components simultaneously. This tremendously improves the accuracy of placement for components from 0201 to BGA.

【Support for Long Boards】 NeoDen's independently developed on-line dual rails enable continuous automatic feeding of boards. This feature, along with Mark point relocated technology, allows the machine to easily mount overlong boards and long LED strips up to 1.5m.

【Versatile Component Handling】 The NeoDen4 can handle a wide range of components, from a smallest size of 0201 to a largest size of TQFP240. It can easily mount high-precision components like BGA and QFN, as well as odd-form components.

【User-Friendly and Compact Design】 The device has a lightweight body and occupies a small area. It features a user-friendly interface that does not require a professional SMT engineer, making it an entry-level device. This makes it especially suitable for laboratory research and development, samples, and prototyping.

【Lifetime Technical Support】 The machine supports remote system upgrades, and NeoDen provides a life-long technical service and system upgrade without charge. The company offers a 2-year guarantee and has a team of 14 professional engineers to provide online Q/A and troubleshooting support.

Specification

| Product name | NeoDen4 pick and place automation machine | Feeders | 48pcs |

| Machine Style | Single Gantry with 4 Heads |

Average working power |

220V/160W |

| Placement Rate | 4000CPH | Component Range | Smallest Size: 0201 |

| External Dimension | L 680*W 870*H 460mm | Biggest Size: TQFP240 | |

| Max applicable PCB | 310mm*1200mm | Max Height: 5mm |

Details

Four Nozzles

Any size nozzle can be installed

Designed in a suspended, fully symmetric

Mount at the same time with 360 degrees

Auto Rails

A. Support connect to conventional conveyor directly.

B. Set the feeding position at anywhere.

C. Mount overlong boards easily.

Vision System

(up-looking and down-looking camera)

Equip with high speed industry CCD cameras

Highly improved accuracy of placement from 0201 to BGA

Electronic Feeders

8mm tape-and-reel feeders

Adopts feeding error corrections technique

handle up to 5 separate tubes

Package

Our Service

1. More Professional service in PNP machine field

2. Better manufacture ability

3. Various payment term to choose: T/T, Western Union, L/C, Paypal

4. High quality/Safe material/Competitive price

5. Small order available

6. Quickly response

7. More safe and fast transport

NeoDen4 SMT machine video

Provide one-stop SMT assembly production line

About us

factory

Quick Facts about NeoDen

① Established in 2010, 200+ employees, 8000+ Sq.m. factory.

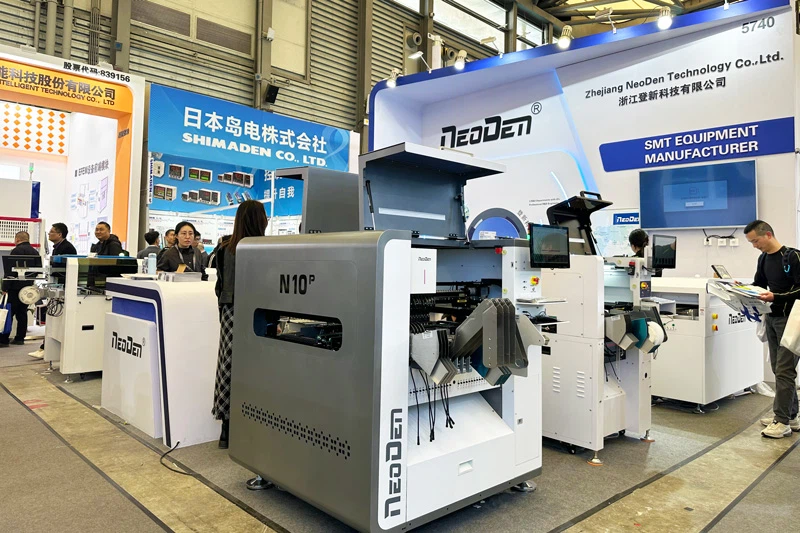

② NeoDen products: Smart series PNP machine, NeoDen K1830, NeoDen4, NeoDen3V, NeoDen7, NeoDen6, TM220A, TM240A, TM245P, reflow oven IN6, IN12, Solder paste printer FP2636, PM3040.

③ Successful 10000+ customers across the globe.

④ 30+ Global Agents covered in Asia, Europe, America, Oceania and Africa.

⑤ R&D Center: 3 R&D departments with 25+ professional R&D engineers.

⑥ Listed with CE and got 50+ patents.

30+ quality control and technical support engineers, 15+ senior international sales, timely customer responding within 8 hours, professional solutions providing within 24 hours..

certification

exhibition

Other Production Line for Your Choice

If you need, please feel free to contact us!

FAQ

Q1. What components can NeoDen4 pick and place machine handle?

A. The NeoDen4 supports components including 0201, BGA, QFN, and LED strips of 0.8 m / 1.2 m / 1.5 m in length.

It handles component sizes from 0201 to TQFP240, with a maximum height of 5 mm.

Q2. What's included in the Feeder capacity?

- 48 x 8 mm tape reel feeders

- 5 x vibrating feeders

- 5 x IC trays feeders

Q3. Who is the NeoDen4 PnP machine suitable for?

A. The NeoDen4 is ideal for small to medium-scale production lines, laboratories, prototyping centers, and budget-conscious businesses that require high precision without manual labor.

Q4. Does the NeoDen4 SMT machine support components with 12 mm height?

A. The NeoDen4 is designed to handle components up to 5 mm in height.

For taller components, we recommend the NeoDen9 model.

Q5. Is the NeoDen4 an online machine with rail?

A. Yes, the NeoDen4 is available in two versions:

With internal rail (for fully automated SMT lines)

Without internal rail (for semi-automatic or standalone operation)

Choose the version based on your production requirements.

Hot Tags: neoden4 pick and place automation machine, China, manufacturers, suppliers, wholesale

Send Inquiry